Construction HPMC For Plaster Mortar

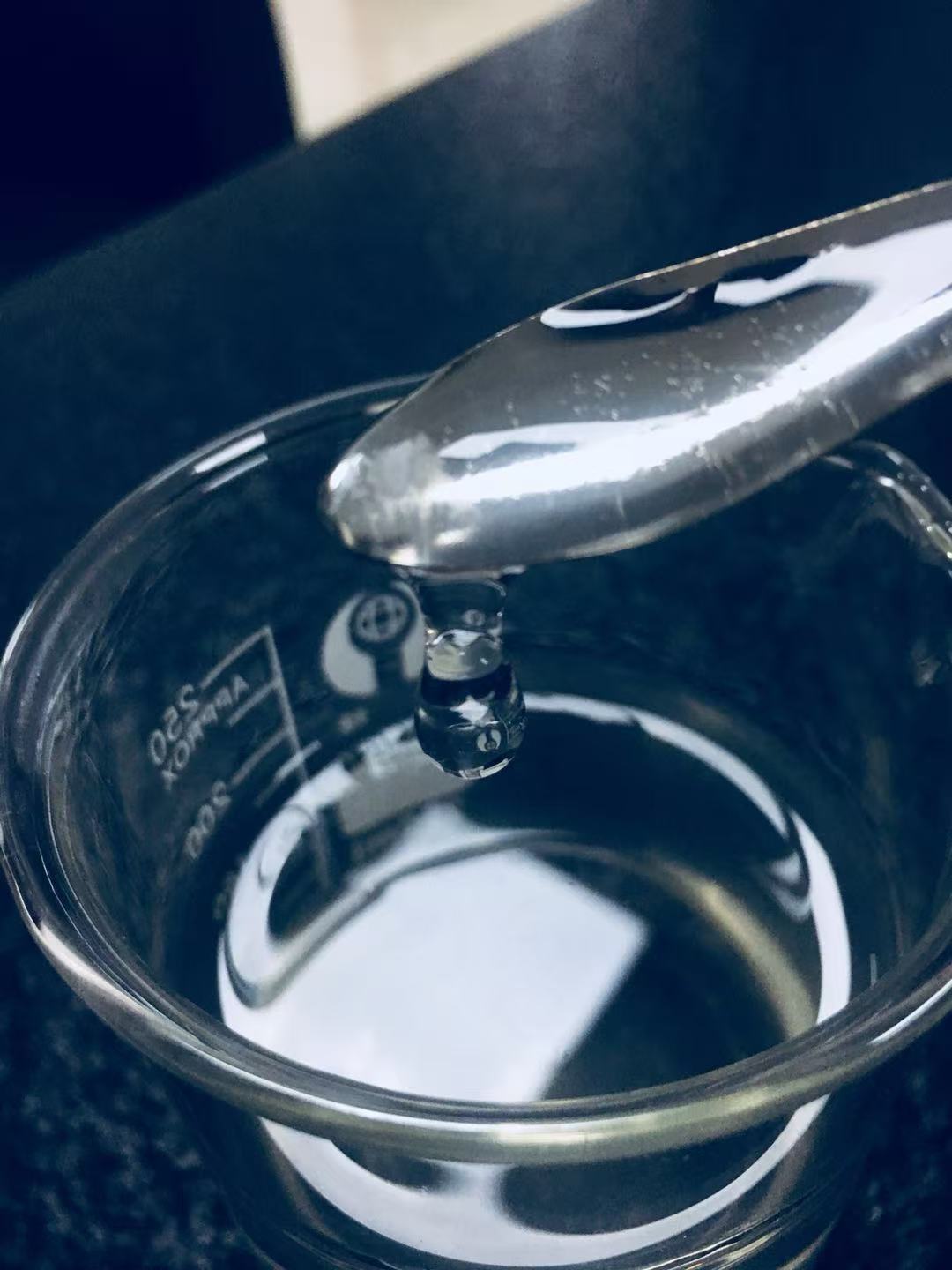

Hydroxypropyl methylcellulose (HPMC) is a nonionic cellulose ether, a semi-synthetic polymer compound produced from natural cellulose (such as cotton pulp or wood pulp) through a series of chemical reactions, including alkalization and etherification. In building plaster mortars, HPMC is not a binder (like cement), but rather a crucial functional additive. While typically added in very low amounts (approximately 0.1%-0.3% of the total mortar weight), it can significantly improve mortar performance. When dissolved in water, it forms a colloidal solution that physically influences various properties of the mortar system, making it an indispensable component in the production of high-quality ready-mixed mortars and on-site mixed mortars.

- HAOSHUO

- Hebei, China

- 2-7 days

- 200 tons per day

Product Detail

HPMC For Plaster Mortar

HPMC For Plaster Mortar Description:

Modern coatings are complex formulas with thickeners, emulsifiers, preservatives, dispersants, pigments, defoamers, and other chemical modifiers. These additives serve an important role in optimizing the coating application and enhancing the inherent properties of the resin.

Appearance: | white or off-white powder |

Moisture: | ≤5 % |

Ash: | ≤5 % |

Methoxy content: | 19-24 % |

Hydroxypropyl content: | 4-12 % |

pH value: | 6-8 |

Viscosity: | 400-750,000 mPa.s (Brookfield RV, 2%) |

Key Features

HPMC exhibits the following key characteristics in plaster mortar:

·Excellent Water Retention

This is the core function of HPMC. It effectively locks in moisture in the mortar, preventing it from being rapidly absorbed by porous substrates (such as aerated bricks and brick walls) or evaporating prematurely.

Benefit: Water retention ensures that the cement has sufficient water for a complete hydration reaction, thereby achieving its ultimate strength. Excessive water loss results in incomplete hydration, resulting in low mortar strength, powdering, and cracking.

·Excellent Thickening Effect

Haoshuo's HPMC solution itself has a high viscosity, significantly increasing the consistency of the mortar.

Benefit:

Improves sag resistance: Prevents mortar from sliding down when applied on vertical walls, making it particularly suitable for thick layers of plaster.

Improves application feel: Imparts excellent "stickiness" and "lubricity" to the mortar, making it smoother and more labor-saving to apply.

·Good workability and lubricity

Haoshuo's HPMC molecules act like a lubricant in mortar, reducing friction between mortar particles.

Benefit: Makes mortar softer, easier to mix and spread, improving construction efficiency and reducing labor intensity.

·Retarding Effect

The water-retention effect slows the migration of water into cement particles, indirectly extending the setting time of the mortar.

Benefit: Increases the open time of the mortar, allowing workers more time to perform leveling and finishing operations during high temperatures or strong winds in summer, preventing rapid dehydration and drying of the mortar, which can lead to poor joints.

Application Effects in Plastering Mortar

Adding an appropriate amount of HPMC to plastering mortar can bring the following immediate positive effects:

Significantly reduces hollowing and cracking.

Mechanism: Uniform and continuous water retention ensures sufficient hydration and strength development of the cement, while reducing shrinkage stress caused by uneven water loss.

Effect: The mortar achieves a stronger bond with the base layer and a denser internal structure, fundamentally reducing the risk of hollowing and cracking.

Improves bond strength

Mechanism: HPMC's adhesive properties and excellent water retention allow the mortar to better penetrate the base layer and form a strong mechanical bond during the hardening process.

Effect: The plaster layer adheres more tightly to the wall and resists peeling.

Improves construction experience and quality

Mechanism: Its excellent lubricity and thickening properties make the mortar non-sticky, easy to apply, and non-sagging.

Effect: The wall surface flatness and smoothness are easier to control, resulting in high construction efficiency and a beautiful finished product.

Increases material yield and reduces waste

Mechanism: Its excellent workability and anti-sagging properties reduce mortar loss during mixing, transportation, and wall application.

Effect: Improves material utilization.

Enhanced freeze-thaw resistance (especially in exterior plasters)

Mechanism: By optimizing the pore structure and reducing the number of harmful macropores, the hardened mortar becomes denser and less permeable to water.

Effect: In cold regions, it effectively reduces spalling and damage caused by freeze-thaw cycles.

How to choose HPMC for plaster mortar?

Viscosity: HPMC with a medium viscosity, such as 40,000-100,000 mPa·s (measured as a 2% aqueous solution), is generally used for plaster mortar. Too high a viscosity will make the mortar too sticky and difficult to spread; too low a viscosity will result in insufficient water retention and anti-sagging properties.

Water retention: This is a key indicator. High-quality HPMC should have a high water retention rate (typically >95%).

Fineness: Fineness (e.g., 80 mesh, 100 mesh) affects the dissolution rate of HPMC. Finer powders dissolve faster and effectively prevent "fish eyes" (undissolved transparent particles) in the mortar.

Summary

In building plaster mortar, Haoshuo's HPMC, as a highly efficient, multifunctional additive, thoroughly improves the mortar's physical and workability through its unique water-retention, thickening, lubrication, and retarding properties.

Our medium viscosity products are used in cement renders to improve the water retention, workability, sag resistance, final consistency and production rates.

Our factory provide many functional additives for decorative and industrial coatings. Our coating auxiliaries find applications in various end-use industries such as textiles, construction & building. They function as agents of rheology control, defoaming and deaerating, hydrophobic treatment, and more. Please contact us for more information.