Cas No 9004-65-3 HPMC For Skim Coat

Our factory adopts 10+ advanced production technology and equipment lines from Germany , with a product quality rate of 100%,daily output can be up to 200 tons now. The factory covers an area of 500,000 square meters,fixed asset of 150 millions yuan, 400 employees and 42 senior technicians. After more than ten years of unremitting efforts and continuous development, our company has become the largest manufacturer of cellulose ether and the only one with 75 degree gel temperature technology in Hebei Province.The company's products have achieved a good reputation at home and abroad with excellent quality and excellent service.

- HAOSHUO

- Hebei, China

- 2-7 days

- 200 Tons/day

Product Detail

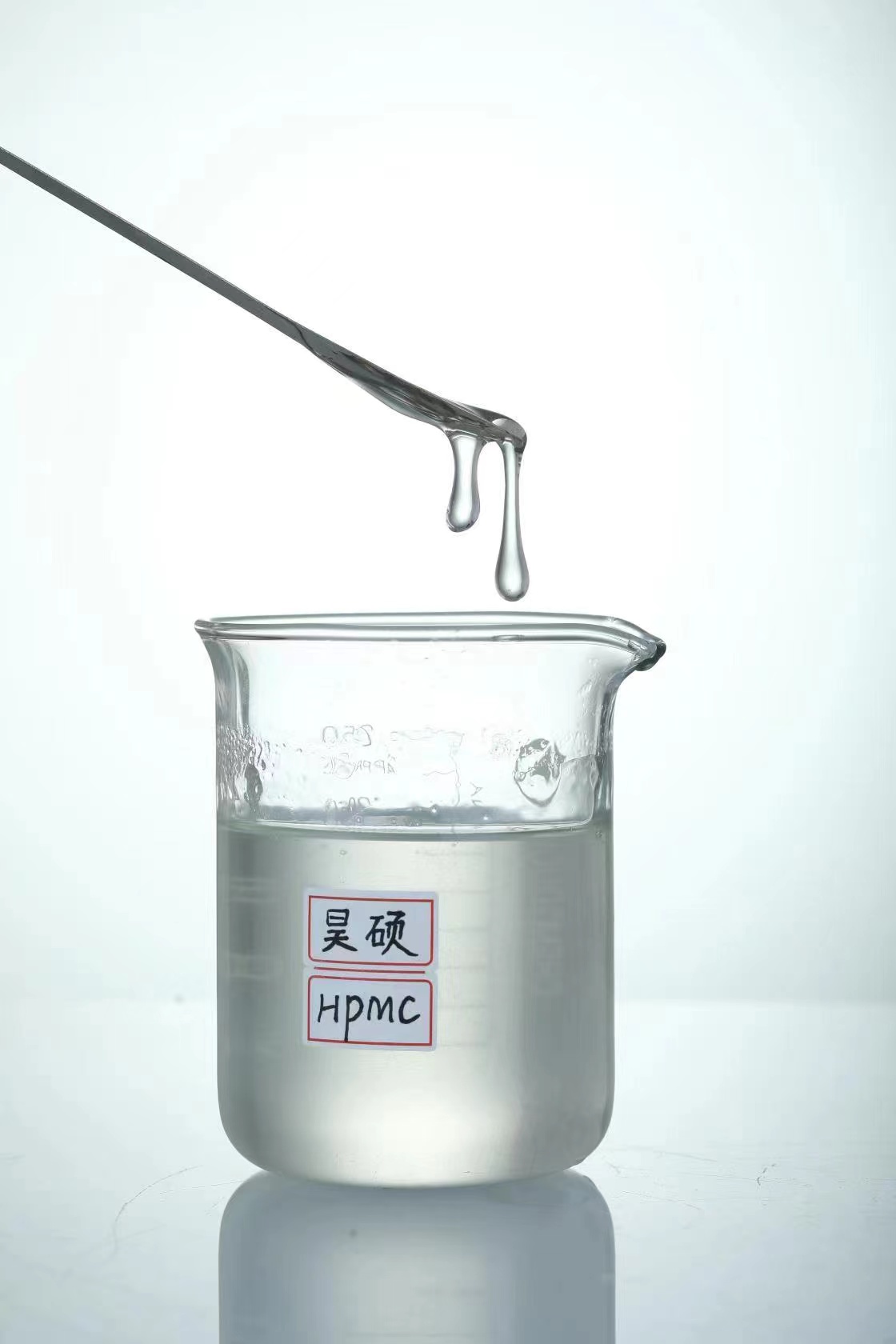

HPMC for Skim Coat

HPMC for Skim Coat Description:

Hydroxypropyl methylcellulose is a commonly used raw material in powdered building materials, which greatly improves the slip performance and anti-sag performance of the construction, improves the wettability, improves the anti-slip performance of the putty, improves the leveling effect of the putty, and improves the construction efficiency.

HPMC for Skim Coat Application: internal wall putty, external wall putty

HPMC can be formulated according to customer needs

HPMC for Skim Coat Advantages:

a. Good workability, good consistency, anti-sag

b. Good water retention, good coating properties, non-stick knife

c. Crack resistance cost-effective

HPMC Packing and Storage: 25kg / bag

Note: the HPMC is packed in polypropylene woven bags lined with polyethylene inner bag coating, each bag has a net weight of 25kg.

Store in a dry and ventilated place indoors, and keep away from moisture.

Pay attention to rainproof and sunscreen during transportation.